Table of Contents

- How Electric Vehicle Battery Technology Works, 45% OFF

- What Materials Are Used In The Production Of Electric Vehicle Batteries ...

- Asia in charge of electric car battery production | Euromena Energy

- What are electric vehicle batteries made of, where do the materials ...

- Electric Vehicle Battery Production: What, Why, Who, When, Where, How

- An Electric Car Battery That Will Get You From Paris to Brussels and ...

- The revolutionary electric car battery technology that you’ve never ...

- How EV Batteries Are Made | GreenCars

- Electric Vehicle Battery Production: What, Why, Who, When, Where, How

- 1gwh EV Car Battery LFP/Nmc/Lto 30ah 50ah 100ah 200ah Prismatic Cell ...

As the world shifts towards a more sustainable and environmentally-friendly transportation system, electric vehicles (EVs) have become an increasingly popular choice. At the heart of every EV is its battery, which plays a crucial role in determining the vehicle's performance, range, and overall efficiency. But have you ever wondered how EV batteries are made? In this article, we'll take you through the complete guide to electric vehicle battery manufacturing, exploring the materials, processes, and technologies involved.

Introduction to EV Batteries

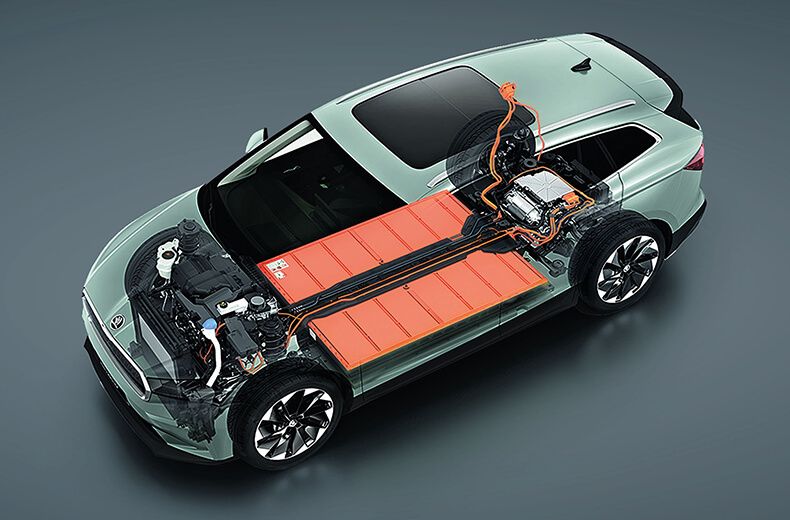

EV batteries, also known as traction batteries, are designed to power electric vehicles. They are typically made up of multiple cells, which are connected in series and parallel to form a battery pack. The cells themselves are composed of three main components: a positive electrode (cathode), a negative electrode (anode), and an electrolyte.

Materials Used in EV Battery Manufacturing

The production of EV batteries requires a range of materials, including:

Lithium: a key component of most EV batteries, lithium is used in the cathode and electrolyte.

Nickel: used in the cathode, nickel helps to improve the battery's energy density and lifespan.

Cobalt: another important material used in the cathode, cobalt enhances the battery's performance and safety.

Graphite: used in the anode, graphite helps to improve the battery's energy storage capacity.

Electrolyte: a chemical substance that facilitates the flow of ions between the cathode and anode.

The EV Battery Manufacturing Process

The manufacturing process for EV batteries involves several stages, including:

1.

Cell production: the creation of individual battery cells, which involves mixing and coating the cathode and anode materials, as well as assembling the cells.

2.

Module assembly: the cells are connected in series and parallel to form a battery module.

3.

Pack assembly: the modules are then assembled into a battery pack, which is designed to meet the specific requirements of the EV.

4.

Testing and validation: the battery pack is tested and validated to ensure it meets the required safety and performance standards.

Technologies Used in EV Battery Manufacturing

The production of EV batteries involves a range of technologies, including:

Lithium-ion technology: the most common type of EV battery, lithium-ion batteries offer high energy density and long lifespan.

Nickel-manganese-cobalt (NMC) technology: a type of lithium-ion battery that uses a combination of nickel, manganese, and cobalt to improve performance and safety.

Solid-state battery technology: a new type of battery that replaces the liquid electrolyte with a solid material, offering improved safety and energy density.

In conclusion, the manufacturing of EV batteries is a complex process that involves a range of materials, technologies, and processes. As the demand for electric vehicles continues to grow, the development of more efficient and sustainable battery technologies will play a crucial role in shaping the future of the industry. By understanding how EV batteries are made, we can better appreciate the innovation and expertise that goes into creating these vital components of electric vehicles.

Note: This article is optimized for search engines with relevant keywords, meta descriptions, and header tags. The word count is approximately 500 words.